Independent Presbyterian Church

Birmingham, Alabama

Opus 90, 2012

Construction Photos

The grid for one of the Great slider windchests is glued up.

The bars for the windchest grid are dovetailed into the frame.

The grid for one of the Swell slider windchests.

Kent fitting the upper surface or 'skin' to the grid of one of the Choir windchests. The skin is aligned with dowels at opposite corners so that it does not slip during gluing.

Kent fitting toeboards to one of the Choir slider windchests.

Pat fitting toeboards to one of the Swell windchests.

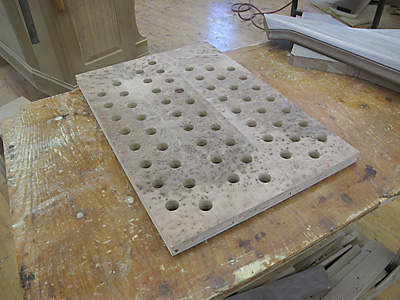

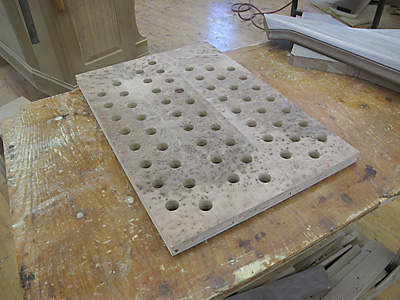

The two Swell slider windchests, after holes are drilled in the top.

For accuracy and ease of drilling, all toeholes are colorcoded to indicate the hole size.

Marking the pallet box bottom.

Jim burns holes on windchest toeboards.

Abe racks pipes. In the foreground are stops from the Solo: the Orchestral Flute 4', the Viole Celeste 8', and the French Horn 8'.

Some of the valves, or pallets, for the slider windchests.

A batch of rack ends in production. These are fitted between the windchest toeboards and rackboards to keep the latter from shifting, which would cause the pipes to lean. Rack pins or pillars alone are not enough to prevent this.

One of the slider windchests, turned upside-down, showing the pulldown magnets. The holes in the back of the pallet box are for yet-to-be-mounted individual magnets, one per channel, that function as relief valves.

Rows of pulldown magnets awaiting installation.

A floating plate concussion bellows, mounted on the back of the pallet box. It has a cutout activated by the tremolo so that it doesn't ruin the tremolo's effect.

The lower case of the console. In the background is the form for laminating the knee panel, which is curved like those made by the Skinner Organ Company.

Because of the very close confines of the choir loft, the console is made to be as shallow as possible.

One of the two stopjambs, covered in Carpathian elm veneer.

These are blanks of western red cedar being glued up for swell shades.

The swell shade blanks are cleaned up in preparation for being resawn into individual shades.

This construction technique results in a laminated swell shade that is very resistant to warping.

More and more swell shades, with Art sharpening the planer in the background.

Swell shade front for the Swell...

...with shades (except for two on the return on the right).

One of the two swell shade fronts for the Solo; the second one is set up immediately behind it.

The lower section of Choir expression shades.

The upper section of Choir expression shades.

Pat miters wooden windlines.

A small assortment of wooden windline components.

Yet more windlines...

John Streufert beveling the edges of a metal pipe body before it is rounded.

The Choir Chimney Flute 4' being made.

The Choir Gedeckt 8'.

Bass pipes of these two stops have round or 'Roman' mouths.

John fitting caps on the Great Chimney Flute. Because they are to fit tightly, they are soldered directly on the pipe body.

The whole gang rolling the body for Low C of the Swell Diapason: from left, John Streufert, Bill Ayers, John Ourensma and John Panning.

To strengthen the mouth area of these large spotted metal pipes, small pieces are soldered on either side of the mouth.

The round parts of the façade towers start out as flat plies of wood glued over round forms.

The wooden drum that will be the base of one of the façade towers.

Other curved elements and carved panels are applied. You can see others in the background.

One of the façade toeboards, which will be mounted on top of the assembly shown in the photo above.

Gluing up planks that will become part of a façade post. This piece is about 22' long.

A number of items that will decorate the case.

Pat Thieszen carving one of the many oak panels.

Op. 90 Home

Op. 90 Setup Photos

Op. 90 Installation Photos